D350SW Robotic welding power source

Return

Control principle

The servo system can achieve lower spatter, faster welding speed, lower heat input and thinner plate welding.

The technology links servo wire feeding with welding process, controls it through digital system, and uses the wire withdrawal force to break the droplet to complete the droplet transition.

Fundamentally solve the problem of welding spatter, and meet the requirements of high-end users for high efficiency and high quality.

Ultra-speed welding

When welding thin plates, the welding speed can reach more than 2m/min with high current and low splash.

High current, low splash

The special high current for welding carbon steel can achieve ultra-low splash over 200A, and reduce the splash amount by over 95%.

Low heat input of sheet

Low arc voltage, reducing splash, heat input and deformation.

CO2 Ultra-low spatter

Achieving ultra-low splash welding by Co2

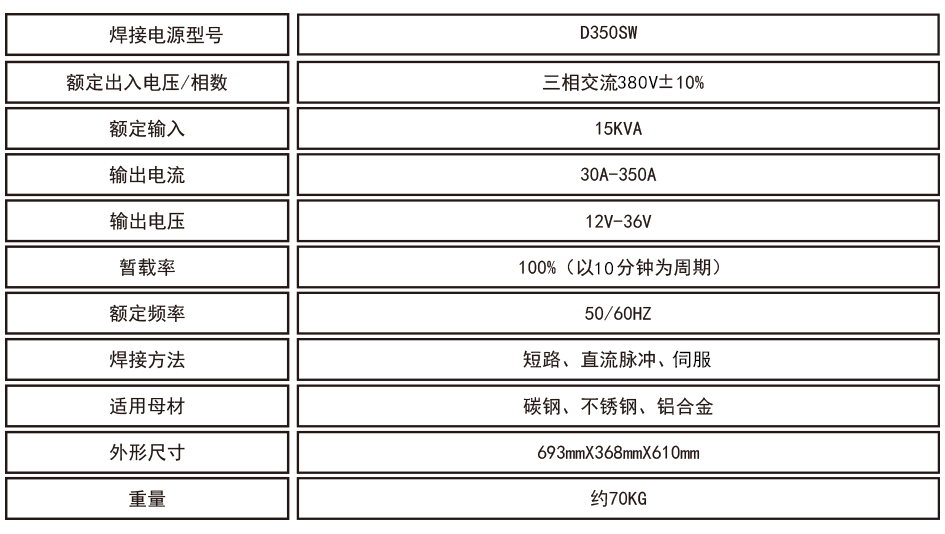

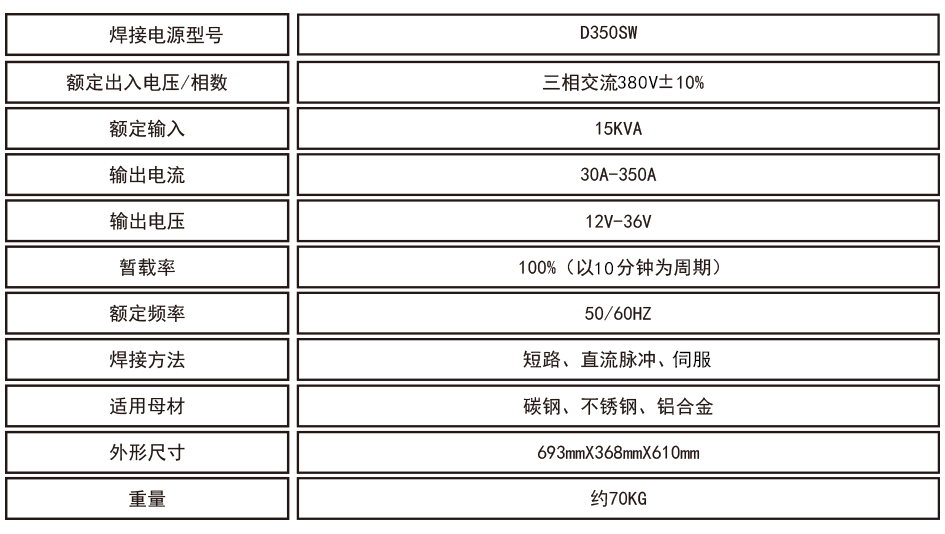

Specification